Ribbon weaving in Coventry began as a supplement to the thriving cloth industry. In 1627 Mr Bird founded the ‘Silk Weaver Company’ assisted by Huguenot refugees who came to England to escape religious persecution. They were welcomed into the country because their silk and ribbon weaving skills were the best in Europe.

In the 17th and 18th centuries ribbon weaving was, in general, done at home by outworkers, mainly women, who used hand looms to produce ribbons and trimmings. They were paid by the piece. The workers were given prepared silk and agreed to produce a ribbon of a certain length by an agreed time.

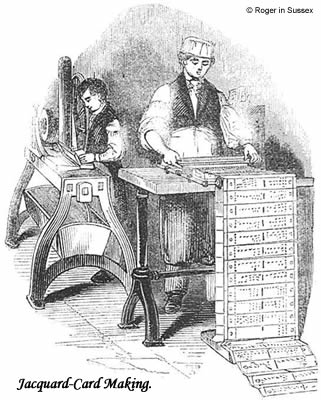

As engine looms were invented, weaving became the prerogative of male workers in workshops. By 1818 there were just over 3,000 engine looms and 5,483 hand looms in the city. In 1821 Coventry had a population of 21,000 and 5,000 of these were ribbon weavers. The Jacquard loom came to Coventry in 1823 and factories were built to accommodate larger looms and produce ribbons on a more commercial basis. The craftsmen were unhappy with this and the first factory built was burnt to the ground by the disgruntled workers. The Jacquard loom used punched cards to control the weaving of the pattern and could produce 8 ribbons at once. These looms were built locally by Wilkinson’s.

There was further discontent in 1831 when Josiah Beck began to use steam powered looms. However, demand was growing as ribbons became essential fashion accessories, decorating hats and dresses, as well as being used for the fashionable hairstyles of the day. So the workers made peace with the factory owners, realising that there was plenty of work to be had.

In 1841 there were 30,000 weavers living in Coventry. The city was the centre of ribbon weaving in Great Britain and had become Coventry’s main industry, employing half the population.

In the 1840s, J.J. Cash opened a factory in Foleshill and the company still survives, carrying out the same sort of ribbon and label making that it always has. Cash’s

The ribbon weaving industry suddenly collapsed in 1860 with the Cobden Treaty, which abolished customs duty on French silks entering the country and Coventry went into a decline. Many of the workers emigrated to the colonies, where their skills were in demand. The city developed other industries including clock and watch making and sewing machine manufacture.

In the 1880s factories began to build bicycles, the skills developed laying the foundation for the motor industry which was to dominate Coventry in the mid 20th century.

Coventry is proud of its heritage and ‘The Herbert’, previously the Alfred Herbert Museum and Art Gallery, houses a recently reconstructed Jacquard loom: Jacquard Loom Goes Back On Display At The Herbert, Coventry.

The Herbert also has a collection of ribbon sample books and woven silk pictures: The Herbert.

Guinevere

© Guinevere 2009

Benjamin Sparks, ancestor of Mary from Italy, was transported for machine-breaking at Beck’s factory, as recounted in the article “The black cap” in the February 2008 Edition.

SOURCES

A History of Coventry by David McGrory

Coventry’s Heritage by Levi Fox